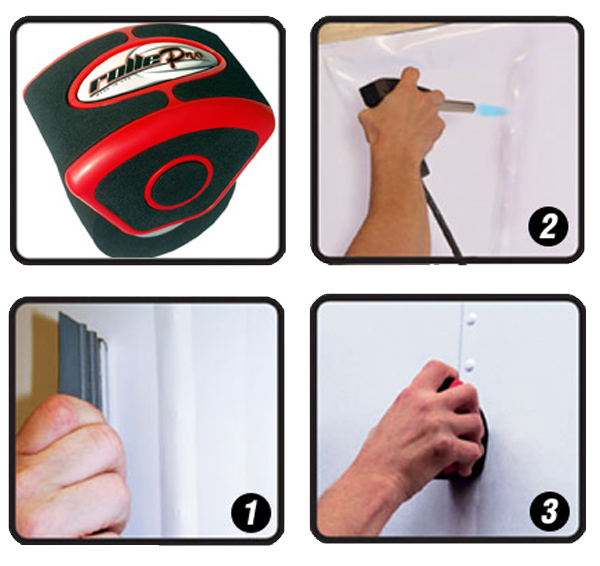

It’s not very often we get this excited down at USCutter about a new application tool. The Rollepro Heat Resistant vinyl applicator promises to revolutionize the world of vehicle wraps: if you have to cover a lot of rivets on a trailer or an RV, you know it’s a total pain and time-sink; this tool makes the process painless. For effortless contour work, simply heat the desired vinyl with a propane torch then roll the Rollepro soft applicator over the irregular surface for smooth bubble-free results. Shapes and seals in 1 easy step for up to 50% faster installation of wraps or large graphics to RV’s, buses, vans, trailers, and more! See for yourself!

for yourself!

Category: Vinyl Applications

STATIC ELECTRICITY AND YOUR VINYL CUTTER: THE GHOST IN YOUR MACHINE

It strikes seemingly at random. A formerly well behaved vinyl cutter goes wild, turning off mid-job, or sinking its blade into a roll of vinyl and running long inscrutable cut-lines, devouring yards of precious material.

Your first impulse is to call the Ghostbusters, but the poltergeists seem to only be haunting your vinyl cutter. Your second impulse is to call the business who sold you this strange object and find out how to get your money back. The ruined vinyl is probably a lost cause.

The likely culprit, says one of our helpful support techs, is not malevolent sprites that have been making the hair stand up on your arm pretty much since you unpacked that roll of vinyl from the plastic…but static.

To diagnose static interference with your value vinyl cutter, our support staff recommends you remove the blade and vinyl and run your job a few times. If your machine works fine, then try adding the vinyl back in, and run the job again. If the spooky phenomena repeats, our support tech will be pretty confident we’re dealing with an invisible, but fundamentally reasonable, and not supernatural opponent.

Vinyl is an insulator which freely gives away positive-charged ions to any surface it rubs against. Itself, the carpet, the plastic it comes in, and your vinyl cutter. As vinyl rolls through your machine, these ions build up in the cutter, and if they aren’t dissipated somehow, they will build up to such a point that they discharge as electricity, causing interference in the electronics of your vinyl cutter.

Certain atmospheric conditions make this more likely, namely low humidity. So a cutter that works fine can suddenly start experiencing static issues due to a change in seasons. In the winter when it’s cold and the moisture literally freezes out of the air, a cutter that’s been working fine all summer can suddenly fall victim to static. Similarly, a cutter in a desert area might work fine in the winter but go haywire as soon as the thermometer starts to rise.

USCutter has a few helpful tips and some products which can solve static problems. First off is the grounding cable which probably came with your cutter. This wire attaches from a screw at the base of your cutter to a screw on the stand (you can also use copper or speaker wire). It is important that the stripped wire ends make metal to metal contact so it might be necessary to strip some paint away on your stand. This basically makes the cutter think it’s bigger and there is more room for the charge to build up.

Another major culprit for new vinyl cutters seemingly going haywire is the included software. Sure Cuts A Lot Pro must be registered using the keycode on the back of the disc package, otherwise the software assumes that it’s in “trial version” mode, and will make random cuts in addition to cutting your design.

If these easy solves don’t work, for less than $15 USCutter offers:

A piece of specially fabricated static string is literally draped across your vinyl as it rolls through the machine. Secured by magnets at either end of the cutter housing, this string dissipates the static charge.

A piece of specially fabricated static string is literally draped across your vinyl as it rolls through the machine. Secured by magnets at either end of the cutter housing, this string dissipates the static charge.

Some of our customers swear by using an anti-static spray, or wiping their vinyl down with dryer sheets, or running a humidifier in the immediate vicinity of the cutter. In addition, most office supply stores stock anti-static mats (they can be a little pricey – one that fits under a 28” cutter can run as high as $150 with shipping).

If all else fails, we call in the Exorcist.

In the case of our SC and Laserpoint vinyl cutters it is most times advisable to “super-ground” your motherboard and rollers into the wall socket. The above pdf link explains and depicts how this is achieved.

USCutter hopes that this blog entry has been a helpful, reassuring and demystifying experience for you and your vinyl cutter. Stay tuned for more postings aimed at the beginning- and professional-level graphics-makers out there!

New Airbrush Artist bundle: How a phone conversation with an enthusiastic artist became a new product package now available from USCutter.

A lot of USCutter customers knew Ben Freeman, our helpful, friendly and smart as a whip tech support good guy that has been helping customers at our tech support desk for years now. Ben is the kind of guy every company loves to have onboard. He really listens to customers and seeks to understand their issues when they call for help and his answers always provide a generous mix of insight and plain language explanation that callers always appreciate.

Most calls Ben receives are fairly standard questions centered on equipment choices and vinyl selections, but on occasion, a user will give Ben a call with something unique. One such customer was Bryan Sande of Fresno-based Reaper Grafx, a custom pinstripe and airbrush artist, whose interest wasn’t really in cutting and placing vinyl at all. He was looking for a way to use a cutter to create his own reusable stencils.

Ben being Ben, he quickly recognized that that was a community of customization and personalization professionals that USCutter should probably work to serve – and he started listening even more. He didn’t have any instant answers, but he formed a working relationship with Bryan, and in doing so came to learn that Bryan is not just a really talented professional in his field, but an innovator and teacher of sorts. Bryan’s Reaper Grafx Fan Facebook page has become a community gathering place for aspiring airbrush artists and those that seek him out are rewarded for their efforts with a wealth of friendly advice, in-depth training info on how to create certain effects, and very valuable recommendations on which products are best available for specific airbrush applications.

Long story short, Ben worked with Bryan and tapped into his expertise to develop the new USCutter Airbrush Painters Stencil Creation Kit, which bundles together carefully selected stencil materials, tapes and other materials into one all complete turnkey kit that enables airbrush artists to quickly design and create their own re-usable stencils and more. It took some testing and Bryan was incredibly generous with his time and expertise in testing equipment and materials.

With this new kit, artists will be able to cut intricate designs into paint mask, cut adhesive vinyl for custom decals and stickers and generally speed up production and make the job of weeding and applying masking material faster and easier. Bryan also made sure that there were things like a pen holder so that airbrushers can easily check their designs on paper before committing to a cut on their materials, and selected just the right transfer materials to make sure that adhesive and other chemicals in the chemicals don’t make their way into the paint on vehicles or other target substrates.

To Bryan, this is just another way of sharing his love for what he does with others, but to thousands of aspiring Airbrush artists out there, this is a savings of time, materials and trial and error to get the right combination of machinery and materials to create quality customization work better and faster. If you do custom airbrush work now, or if you are one of the many vehicle wrap professionals that buys materials from USCutter, we encourage you to pay a visit to Bryan’s pages and perhaps join in his community, and if you want to get started using vinyl cutters to create your stencils, check out the Airbrush Painters Stencil Creation kit on the USCutter website.