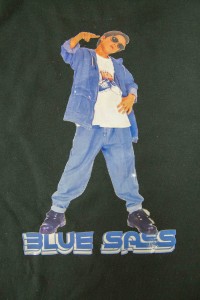

There are an array of products one can start making immediately with an enterprising mindset and the basic equipment for this business: a decent vinyl cutter and heat press.

Vinyl graphics and letters for signs and indoor walls, decals for shirts, etc. Not surprisingly, the stuff that’s easiest to do, with the lowest up-front investment in equipment, also presents the greatest barriers to successfully differentiating yourself in a crowded marketplace.

So what’s true for any business, is true for this one. To have success, one has to diversify one’s product offerings, and ideally specialize in a niche with plenty of room to grow. Two products you may not have considered to expand into yet are customized ballcaps and dye-sublimation printed mugs.

We’d like to present the business case here for expanding into both processes. Both processes require an investment in specialized equipment, but the following math will demonstrate you can break even on cap production with sales of only 40 caps, and you can buy all the equipment for dye-sublimation printing (with applications ranging from printed mugs, to photo panels, to shirts, and more) with sales of only about 180 mugs!

CUSTOM CAPS:

What you need…

A vinyl cutter, a Transforsa Digital Cap Heat Press, 15″ x 5yd Roll of Siser EasyWeed.

Assuming you cut a design 4 in wide x 2.5 in high, you can produce 180 heat transfer vinyl decals from a 5 yard roll of EasyWeed ($35.65). This works out to be about 20 cents/hat in vinyl.

The cost of blank hats is going to be your main expense. The cost of hat blanks and vinyl to produce 180 hats is $575.20. 1 hat costs about $3.20 to make. Let’s say you can sell that hat for $12.

Profit/hat = $8.80. The cost of your equipment ($264.99) + the necessary hats (36 more) = $372.90. Divide that by your profit/hat ($8.80), and you’ve almost completely paid for your equipment with sales of about 40 hats!

DYE-SUB PRINTED MUGS:

What you need…

A Sawgrass Dye-Sublimation Printer, a mug press or 5-in-1 multi-press, sublimation transfer paper, dye-sublimation inks, and cases of mugs.

The cost of the equipment in this bundle (SG400 printer + 5-in-1 heat press + mug paper) is only $799. It only costs about 10 cents in ink to print 1 5″x7″ mug design. The cost to decorate a case of 36 mugs would be $3.60 in ink, $3.24 in paper, and $56.99 for the cost of the mugs.

Total cost of supplies to decorate 36 mugs = $63.83 –> $1.77/mug. If you sell the mugs at $8/ea, that works out to be $6.23 profit/mug.

At that clip, paying for all the equipment and supplies (printer, heat press, ink, paper, and mugs) you needed to make 180 mugs would cost you about $1118. Divide this by our profit/mug, and with sales of about 180 mugs, you’ve just paid for all your equipment and supplies, and each additional mug sold is almost pure profit! And a dye-sub printer comes in handy for so much more, from shirts, to jerseys, to Wunderboard metal photo panels, to clear vinyl, and beyond!