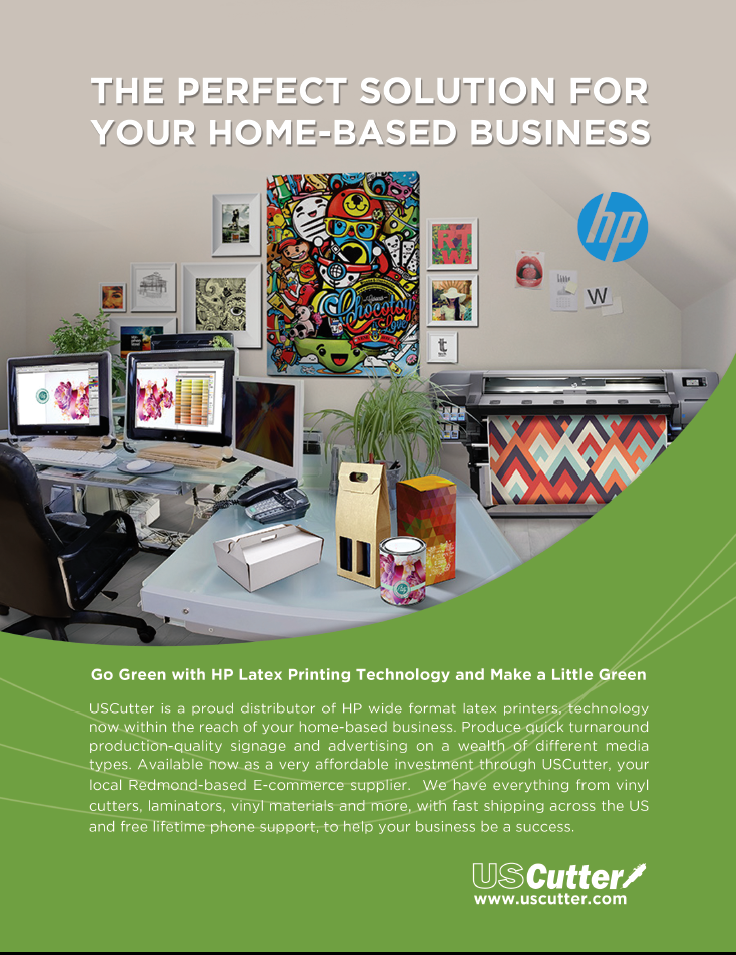

My mission (I wasn’t really given a choice if I could accept or not) was simple. HP had developed in absolute secrecy a new user-installable true wide-format digital latex printer for under $10,000. It seemed like a foolproof plan, to bring wide-format printing on all different media types – for applications ranging from wrapping cars, boats, and brick walls, to putting ads beneath people’s feet in grocery stores, to printing the custom wallpaper of your dreams – firmly within the reach of entry-level print operators and sign shops.

And HP’s premise with the new 110 printer was so bold, so revolutionary: that literally anyone could install this printer right out of the box (with no professional help whatsoever) and be printing within hours. But this claim still needed to be tested. All they needed was a guinea pig, someone who fit their profile of the “clean slate”.

And this is where I enter the story. The crate arrived on a blue summer day.

I knew we were getting in a new product. A new wide-format printer for entry-level users which was shattering the ground floor on pricing for these machines. A claim that a printer like this is “user-installable” is big. First of all it has to be easy enough for someone who’s frame of reference is a desktop printer; and second of all, how much cheaper is it if you can save thousands on the installation fees and associated travel that comes with the requirement that other printers of this ilk be installed by a certified technician?

The crate was big, large enough to hold a jungle cat. Everyone stood around and oohed and awed. My boss helped me take off the top, revealing the neatly packed contents beneath. But soon it was just me, the screwdriver, and the instructions.

The challenge was clear. Could I be the “literally anyone” that they required to complete this task?

Hours passed and the machine was taking shape, whirring to life. I installed cartridges, printheads, all the while receiving prompts directly from the printer. I downloaded the RIP from the cloud. I had my fair share of hiccups, first and foremost of which was my failure to properly latch the print carriage. What was supposed to take 3 hours ended up taking me 6. But the point is, after all was said and done, that probably the hardest part about the whole installation process was opening up the box and finding the instructions. Welcome to the age of affordable accessible wide-format printing: the new HP 110 Latex Printer has arrived.